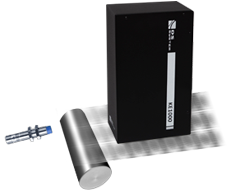

System design

The system consists of individual modules that make up a complete video system for inspecting the printing process. The individual modules are interconnected with signal and power cables.

screen

controller

camera module with synchronization sensor

control panel

Functions

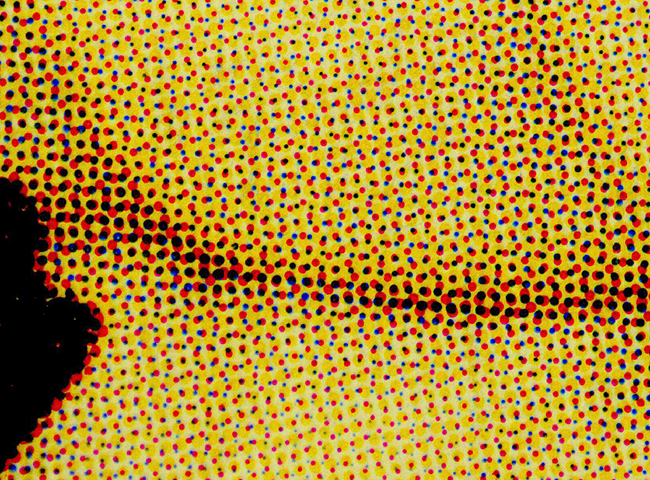

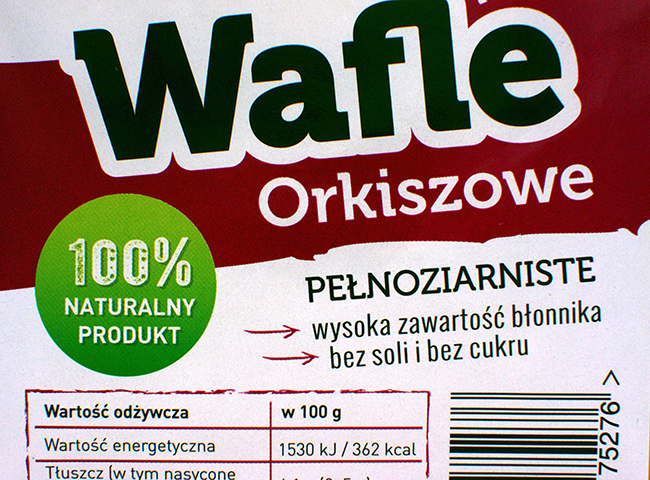

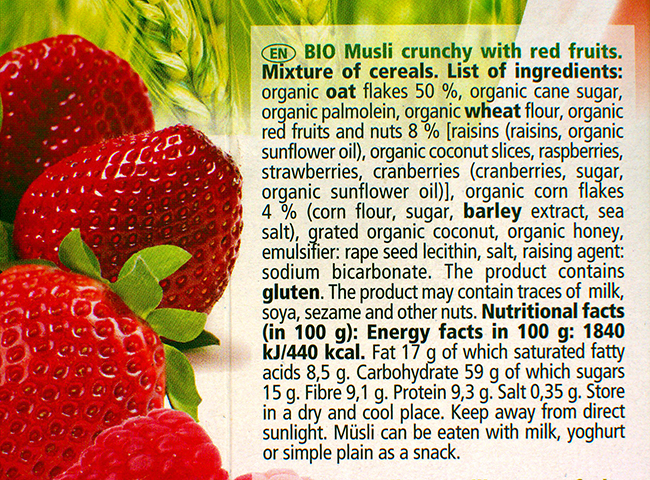

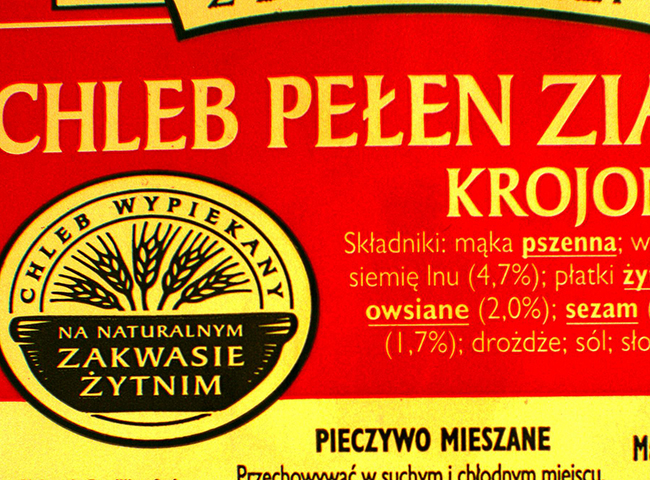

Digital video quality

The cutting-edge UltraHD high res camera ensures excellent reproduction of color depth and even the finest details in printing.

High precision ZOOM

Adjustable 10x zoom works perfect for purposes of controlling the printing process.

Image rotation

The image can be rotated by 90, 180 and 270 degrees. This way there is no need to physically reposition he camera module - the image is rotated in the controller's software.

Comparison with the master image

The split screen mode allows to view the actual image in print and the master image stored in the memory.

Print screen

A selected image, with superimposed current date and time, is saved in the camera's memory. The saved images can be then browsed to verify against the ongoing print job.

OSD and message bar

Quick and easy adjustment of refreshing frequency, image rotation and other operating parameters. The message bar show complete information about the camera's current status.

Modes of operation

Normal

The selected printing area is refreshed in cycles; for inspecting printing errors, registration and other printing marks.

Auto-scan

Image grabbing for viewing the entire print area, frame by frame, along the web.

Comparison with the master image

The split screen mode allows to view the actual image in print and the master image stored in the memory.

One system, two solutions

System with manual positioning

The camera's position is adjusted manually, over a selected area.

System with automatic guide rail

The camera's position is adjusted by means of an automatic guide rail with a step motor.

Advantages for your business

Guaranteed high quality print

Reduced waste and printing costs

Control at high machine speeds

Affordable print inspection system

Sample images made with KE1000

Manufacturer

DS SYSTEM, Poland

ul. Iłłakowiczówny 13B, 52-211 Wrocław

Phone

+48 604 738 238